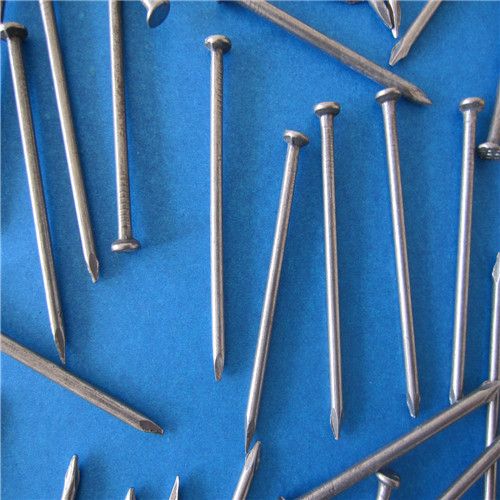

Steel wire nails are a staple of construction and other related projects and can be found in a range of sizes and weights to suit various applications. This article delves into some of the most popular weight classes of wire nails.

A vast catalog of nails comes in many different sizes and weights. Most of them can be identified by the term ‘penny’ which denotes the length of the nail in inches and its diameter, for example, 2 penny (2d), 3 penny (3d), 4 penny (4d) and so on. Generally speaking, the larger these nails are, the more significant their mass will be.

Depending on the coating, the weight of wire nails can differ significantly. Zinc-coated nails typically weigh between half an ounce and five-eighths of an ounce apiece. Meanwhile, copper-plated wire nails are usually slightly lighter, between half an ounce and three-quarters of an ounce each. Galvanized steel-coated nails, however, tend to be slightly heavier, typically between three-quarters and one full ounce for each nail. Of course, all these coatings serve a purpose too – preventing corrosion and rust, as well as providing additional strength to the structure.

The length of wire nails is an influencing factor when it comes to their weight – generally speaking, the shorter they are, the lighter they will be. For example, a 2d nail usually has a weight of approximately 0.5 ounces, whilst a 16d nail is likely to reach a weight of one ounce.

The heft of wire nails is contingent on the type of material to which they are applied. When joined to demanding substances such as concrete or masonry, they need to be heavier and longer to effectively enter the framework. Elsewhere, when bonded with comfier compounds, like lumber, lighter and shorter nails are best suited.

When selecting wire nails, it is critical to choose the fitting size and weight for the task. As a guideline, use the heaviest possible nail that won’t sacrifice material sturdiness. While lightweight nails may be more affordable, they may not bond the material as dependably as heavier nails.

To wrap up, wire nails exist in an array of shapes and heft. From 2d to 16d, the most frequently encountered sizes encompass an expansive range, and the weight depends on the length as well as the variety of coating used. As such, it is essential to settle on the precise size and mass of wire nail, to guarantee that the material is held together securely.

Wire nails represent a staple in the construction industry, having been around since the dawn of civilization. These steelwire fasteners come in all sorts of shapes, sizes, and weights to cater to a wide variety of uses, from home improvement projects to industrial-grade constructions. In this article we delve deep into the variable weight of wire nails and the various criteria that affect the selection of the appropriate size.

The heft of a wire nail can be determined by the material it is constructed from, such as steel, aluminum or brass. Its weight is also impacted by the thickness of the wire and the type of finish that is applied to it. Galvanized wire nails are usually heavier than those without this coating. Plus, longer nails quite naturally are heavier in comparison to shorter varieties.

A wide spectrum of sizes can be found in wire nails, which dictates their weight. Usually, the lengthier it is, the more weight it will bear. This is evident when comparing a 2-inch nail and a 3-inch one; the latter will weigh more than the former. Generally speaking, the most regularly utilized wire nails measure from 1 inch to 6 inches in length, and their weight may range from 0.2 ounces to 2.6 ounces, depending on their size and coating.

When crafting wire nails, the weight of the finished product is heavily influenced by what it’s primarily constructed from. Steel wire nails are the most commonly found version, and are traditionally heavier than their aluminum and brass counterparts. Even within the same type of material – such as steel – the weight can vary greatly depending on the grade.

Compared to round wire nails, flat wire nails tend to be lighter and more popularly utilised in construction endeavors. Square wire nails, though heavier than the former, are not as frequently implemented in building tasks.

The weight of a wire nail can be determined by the type of finish it has. Non-galvanized nails tend to be lighter compared to their galvanized counterparts, due to the galvanized coating that adds extra heft. Not only does the finish of the nail alter its weight, it plays a significant role in its strength and durability, as the galvanization makes it more rust-resistant.

Nailing down any project requires thoughtful consideration of several factors to ensure the best possible results. Whether choosing common wire nails or another type, it is important to evaluate the material, length, shape, weight, and finish of the nails- all factors that influence the strength and lifespan of the nails. The cost of the nails can also greatly vary depending on their size and finish. Wise selection requires close examination of all elements.

When it comes to home and commercial construction projects, wire nails are a great option due to their versatility and affordability. Everything from the material, length, shape, and finish of the nail determines its common weight. You must take these features into account while making your selection, as they are responsible for impacting the nail’s strength and sturdiness.

Related Product

Double Head Nail

Product Information: Material Q195/Q235 Surface Treatment Bright, E.G, H.D.G, M.G, V.C, C.C, P.C and so on Head Two Head Shank Smooth Shank Point Diamond Point Kinds of pa […]

Headless Nail

Product Information: Cheap Lost Head Nails/ Headless Nails/ Finishing Nails Price Material Q195 or Q235 iron wire rod or according to request Size 1″ – 6″ Finish Polished or […]

Common Nail

Product Information: Common Nail Material Q195, Q235 Shank diameter 1.2mm-10mm Length 19mm-300mm Finish polish/bright, electro galvanized, hot dip galvanized Head flated he […]

Garden Nail

Product Information: Black or yellow color plastic ground pegs are used for fix the ground cover or woven fabric or fleece on the ground. Material: Virgin PP OR PP +UV stabi […]

Concrete Nail

Product Information: Product name CONCRETE NAIL Material: #45 or #55 Steel Size: 1/2″-6″ Type: Round head with smooth shank or groove shank Treatment: Electro galvanized, ho […]

Black concrete nail

concrete nail with special materials, concrete nails are specialty nails compared with common iron nails. It is harder, the shank is short and thick commonly and it has excellent p […]

Paper Strip Nail

Product Information: Material Q195, Q235, stainless steel Surface Finish Bright, Galvanized, Hot Dipped Galvaized, Electro Galvanized, Zic Yellow, Zine Bule, MG, Dacro, etc. […]

G Sod Staple

Product Information: Product name Sod Staple Material: Q195 /Q235 Size: 3/4X14GA, 3/4X9GA, 7/8X14GA, 1X9GA, 1-1/4X9GA, 1-1/2X9GA, 1-3/4X9GA Type: Round head with smooth shan […]

U Sod Staple

Product Information: Landscape Staples * 11 GAUGE STEEL CONSTRUCTION: The points on the staples are sharp enough to pierce commercial ground cloth, and the staples are long […]