product detail

Product Information:

| Common Nail | |

| Material | Q195, Q235 |

| Shank diameter | 1.2mm-10mm |

| Length | 19mm-300mm |

| Finish | polish/bright, electro galvanized, hot dip galvanized |

| Head | flated head, checkered head, round head |

| MOQ | one ton for each size |

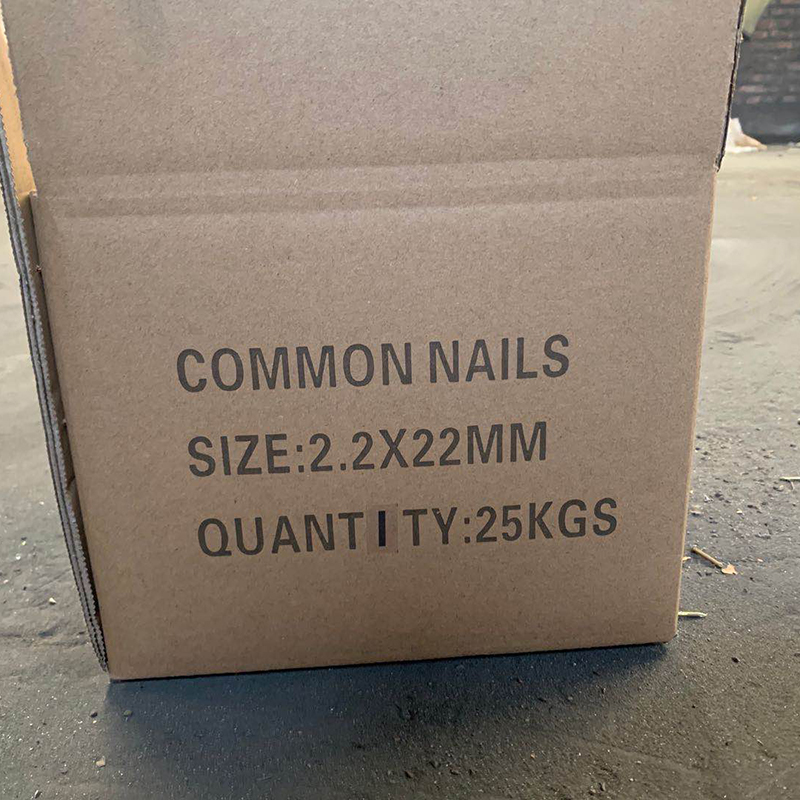

| Packing | 5kg per box, 1kg per box or bag, 500g per bag, 25kg per carton and as your request |

| Payment term | 30% TT in advance and 70% TT before shipment |

| Usage | building construction, decoration field, bicycle parts, wooden furniture, electrical component, household and so on |

| INCH | MM | BWG |

| 1/2″ | 12.7 | 20/19/18 |

| 3/4″ | 19 | 19/18/17 |

| 1″ | 25.4 | 17/16/15/14 |

| 1 1/4” | 31.7 | 16/15/14 |

| 1 1/2” | 38 | 15/14/16 |

| 1 3/4″ | 44.4 | 14/13 |

| 2” | 50.8 | 14/13/12/11/10 |

| 2 1/2” | 63.5 | 13/12/11/10 |

| 3″ | 76.2 | 12/11/10/9/8 |

| 3 1/2” | 88.9 | 11/10/9/8 |

| 4” | 101.6 | 9/8 |

| 4 1/2” | 114.3 | 8/7 |

| 5” | 127 | 7/6 |

| 6” | 152.4 | 6/5 |

| 7” | 177.8 | 5/4 |

Features :

Common nails are strong and stiff, and their shanks have greater diameters than other nails. Both common and box nails have notches near the head of the nail. These notches allow the nails to hold better. Some will have screw-like threads at the top of the nail head for extra holding power. Box nails have thinner shanks than common nails and shouldn’t be used for framing construction. When nailing two boards together, both types of nails should completely penetrate one piece of wood and should penetrate the other piece with half its length. This ensures the nail is strong enough for the job.

Most people use common nails for medium to heavy construction work. With a thick nail head, the nails drive easily into tough materials. Some examples include thin sheet metal, wood and thin aluminum. Use common nails on projects such as fences, roofs and decks. Box nails are lightweight and ideal for small projects or household use. Hang small pictures and wall decorations using box nails. Use box nails on thin wood materials such as wood boxes to reduce splitting.

Application:

Packing :

Net weight 20-25kgs/carton without poly bags or inner boxes1kgs/poly bag, 25 bags/carton

5kgs/box, 4 boxes/carton 3.125kgs/inner box, 8 boxes/carton20kgs/wooden box with 16 inner boxes inside or according to your requirements.